Big red laser cutter

General Info

The big red laser cutter is a no-name model using a Ruida 644XG control board. Its bed dimensions are about 730mm wide by 500mm deep. It looks like a 100 W CO2 laser.

The Melbourne Makerspace has the same laser and have a nicely written wiki page on it.

Be aware: lasers are very dangerous, particularly to eyes. Review these safety guidelines, use eye protection, and carry an appropriate level of fear of the laser at all times.

Operation Instructions

Preparing Material

- Put LASER SAFE Material on the bed

- Put laser head above your material

- Move the bed up and down until the laser at correct focus height above your material

Turning on the laser

- Turn on the blower

- Enable the laser

- Power on the controller

- Power on the laser

To begin using the laser, turn on the power strip sitting on the left side of the laser. You'll hear the blower plugged into this strip begin running. Next, turn the key below the controller on the front right corner. Then turn on the two switches on the right side of the cutter. Both will illuminate. The upper one will turn on the controller, and the display will illuminate. The other one sends power to the laser. It won't light up if the key enabling the laser is off.

Preparing the file

- Open Lightburn

- Import or draw the image

- Adjust settings. Use this chart Big red laser cutter settings

- Send it to the laser

- Click “Send”

- Enter a name and press enter.

- Wait for the file to send.

Open a DXF, PDF or other vector file to create a path to cut along. You can compose projects in Lightburn or in other programs (see below) and then open them in Lightburn, import them, or copy and paste contents over. Set the color of items to define how you want them cut or printed, then double click the colors in the pane on the right to set the laser speed, power, and other features associated with that color. Black can be used to cut and red to etch, for instance. Look up the recommended speed and power for a given material and thickness, then test as necessary to figure out a good balance. Select "absolute coordinates" to define the placement relative to the bed. Select "user origin" to set the placement on the bed manually. The device should be set to ttyUSB0, Ruida664GX.

When you're read to cut, click "Send" and a box will open asking for a name. If the name exists, it will ask for confirmation to overwrite.

Running the laser

- Press "File" to see available files.

- Scroll and press “Enter” to select a file.

- Set the origin if necessary.

- Press “Frame” to confirm placement.

- Press “Start”.

Having Trouble Setting the Origin?

If you are using Lightburn to compose your project, be sure to use the setting "Current Position".

Otherwise, Lightburn may override any origin you set at the laser cutter.

Setting the origin on the laser cutter is easy.

On the front panel there are 4 arrow keys. You can use these to move the "head" around.

Pressing the "Origin" button sets that spot to be the origin of where cutting starts. Typically, this is the upper left

of the bounding rectangle around your artwork.

You may find that moving the "head" is much easier than moving the material placed on the bed!

other software

As mentioned, RDWorks can also be used. We haven't tried it yet but it seems it's a free download from here.

Some of the software (downloaded from the above link) is on the hard drive of wasp.local which is a desktop computer under the 3D printer desk, in a folder called ~/laser-backup/

The above software has also been downloaded and stored here

it was setup with an IP address of 100.64.64.69 (by pressing buttons through the menu) but it had no ports open and then we just switched over to USB to the computer and it was working fine. The same software might work over ethernet but we didn't try.

Trying other things

Andy is trying to find software to control the laser cutter. I can generate gcode instructions in Inkscape, but I don't know how to send them to the printer over USB.

I'm trying to install [1].

I ran the commands here : https://laserweb.yurl.ch/documentation/installation/36-install-raspberry-pi. But the server gave an error when started:

Server binding to all local IP addresses on port: 8000 internal/modules/cjs/loader.js:818

throw err; ^

Error: Cannot find module 'node-hid' Require stack: - /home/laser/Programs/lw.comm-server/server.js

at Function.Module._resolveFilename (internal/modules/cjs/loader.js:815:15)

at Function.Module._load (internal/modules/cjs/loader.js:667:27)

at Module.require (internal/modules/cjs/loader.js:887:19)

at require (internal/modules/cjs/helpers.js:74:18)

at Object.exports.LWCommServer (/home/laser/Programs/lw.comm-server/server.js:168:13)

at Object.<anonymous> (/home/laser/Programs/lw.comm-server/server.js:4141:13)

at Module._compile (internal/modules/cjs/loader.js:999:30)

at Object.Module._extensions..js (internal/modules/cjs/loader.js:1027:10)

at Module.load (internal/modules/cjs/loader.js:863:32)

at Function.Module._load (internal/modules/cjs/loader.js:708:14) {

code: 'MODULE_NOT_FOUND',

requireStack: [ '/home/laser/Programs/lw.comm-server/server.js' ]

}

Stuff made on the big red laser cutter

- I cut some 1/4 clear plastic suspected to be acrylic. Used .5mm/sec 100%/40% power. It cut all the way through but the edge was rough.

Stuff seen around the space

ventilation ducting

cleaning

If the exhaust fan is not working well, it might need to be cleaned.

To clean, detach the fan and base from the laser cutter. The area circled in the below picture is where you need to get access. showing where to detach laser exhaust fan

This is what the fan looks like detached

This is dirty and needs to be cleaned dirty laser exhaust fan

Use a vacuum and toothbrush/wire brush to clean. A n95 is recommended too. clean laser exhaust fan

history

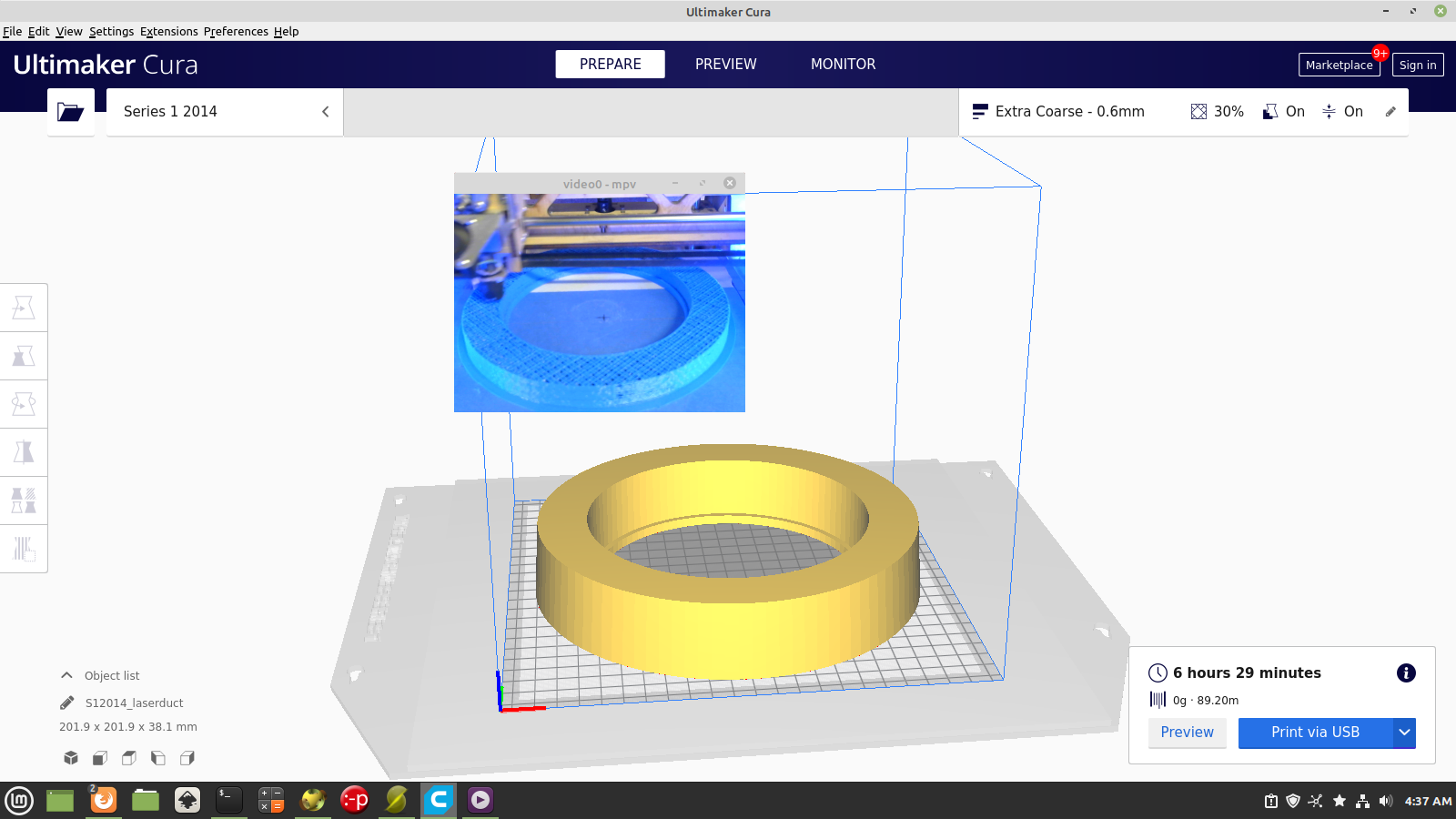

a plastic adaptor was 3D printed to connect the 6" outlet of the exhaust fan to the 8" flexible duct leading to the roof hole:

laserduct.scad

THICKNESS=1.5*25.4;

ID=5.75*25.4;

ID_LIP=ID-(0.25*25.4);

ID_LIP_THICK=0.2*25.4;

OD=7.75*25.4;

OD_LIP=OD+0.2*25.4;

OD_LIP_THICK=0.2*25.4;

difference() {

color("BLUE") cylinder(d1=OD_LIP, d2=OD, h=THICKNESS, $fn=100);

{

translate([0,0,ID_LIP_THICK]) cylinder(d=ID, h=THICKNESS, $fn=100);

translate([0,0,-0.5]) cylinder(d=ID_LIP, h=THICKNESS, $fn=100);

}

}

Also the duct/roof interface was improved and a new stand was made for the extractor fan. Yay for milkcrates!