Difference between revisions of "Subiir"

Rabbitface (talk | contribs) |

|||

| Line 12: | Line 12: | ||

= Projects = | = Projects = | ||

For anyone who wants to brew home brew beer, the materials and basic process are as follows. There is actually a large home-brew community and recipes so, anyone should check in with a basic google search to start: [https://www.google.com/search?q=home+brew+recipes]. | |||

The rest is hardware and, there's some that is required for it. The main things are a vat which you can bring to a boil when you're stirring the ingredients, a syphon hose rubber tube, and a large tub with an air vent, that lets out the vent [[air]] as the sugar is transformed by yeast to alcohol. :) Finally, you will need a way to bottle the beer. | |||

==== | |||

Project to create an automated system to preheat mash and sparge water, carry out step mashing program, and alert operator of different manual steps such as adding hops. | Project to create an automated system to preheat mash and sparge water, carry out step mashing program, and alert operator of different manual steps such as adding hops. | ||

Revision as of 13:56, 13 May 2013

General

sudoroom has an active beer-brewing group. The mash is made off-site (due to a lack of out-door facilities at sudo room) and fermentation and bottling happens at sudoroom.

Have a look at the individual brews for more info.

See also: Sudomate

List of brews

- subiir 0 - fermentation started January 12th 2013.

Projects

For anyone who wants to brew home brew beer, the materials and basic process are as follows. There is actually a large home-brew community and recipes so, anyone should check in with a basic google search to start: [1].

The rest is hardware and, there's some that is required for it. The main things are a vat which you can bring to a boil when you're stirring the ingredients, a syphon hose rubber tube, and a large tub with an air vent, that lets out the vent air as the sugar is transformed by yeast to alcohol. :) Finally, you will need a way to bottle the beer.

==

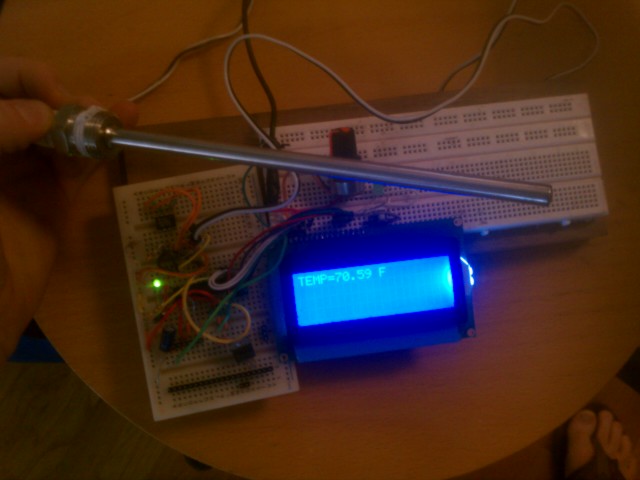

Project to create an automated system to preheat mash and sparge water, carry out step mashing program, and alert operator of different manual steps such as adding hops.

System Components:

-ATMega 328p based controller

-DS1307 Real Time Clock

-DS18B20 Digital Temperature Sensors

-16x4 character LCD Screen

-4x Relay board for pumps and heating elements

-Serial connection for reprogramming

Possible add-ons:

-continuous hopping auger

-servo-controlled gas valve for boil stage

-buzzers and UI improvements