Difference between revisions of "Type A Machine"

(move outdated comic instructions to its own page) |

(rearrange, add introduction & disambig) |

||

| Line 1: | Line 1: | ||

[[File:3dprinterfisheye02.jpg|thumb]] | [[File:3dprinterfisheye02.jpg|thumb]] | ||

''This is about a particular printer. There's a separate page about [[3D_Modeling|creating or acquiring 3D models]].'' | |||

SudoRoom has a [http://typeamachines.com/ Type A Machine], currently our only 3D printer. It was generously donated by Jae Kwon in fall 2012. | |||

==Attached Computer== | ==Attached Computer== | ||

| Line 6: | Line 10: | ||

* kisslicer (alternative to slic3r) | * kisslicer (alternative to slic3r) | ||

* [https://github.com/kliment/Printrun pronterface] (operates the printer, which accepts gcode) | * [https://github.com/kliment/Printrun pronterface] (operates the printer, which accepts gcode) | ||

== Calibration == | == Calibration == | ||

The bed & z-axis are often untrue. Some suggestions: | |||

* Move the head around - is the bed flat? Test the Z roughly with an allan wrench laid flat on the bed (it should should barely flip up), then more finely with a piece of paper (it should create a slight friction only). Test on all four corners, adjusting the screws if necessary. Sometimes the middle might even be dipped in a bow. This will make it harder to print large objects... | * Move the head around - is the bed flat? Test the Z roughly with an allan wrench laid flat on the bed (it should should barely flip up), then more finely with a piece of paper (it should create a slight friction only). Test on all four corners, adjusting the screws if necessary. Sometimes the middle might even be dipped in a bow. This will make it harder to print large objects... | ||

* Because the bed is not heated, prints will stick. You might need to pry them off with a razor. This often tears the tape, so we need to buy more tape. Usually we use ScotchBlue #2093EL. | * Because the bed is not heated, prints will stick. You might need to pry them off with a razor. This often tears the tape, so we need to buy more tape. Usually we use ScotchBlue #2093EL. | ||

| Line 26: | Line 20: | ||

This printer has a long, colorful history of repair and disrepair. Most recently, Jake got it to work and [http://lists.sudoroom.org/pipermail/sudo-discuss/2013-December/005006.html reported to the list]. | This printer has a long, colorful history of repair and disrepair. Most recently, Jake got it to work and [http://lists.sudoroom.org/pipermail/sudo-discuss/2013-December/005006.html reported to the list]. | ||

At least one Sudoer works for the manufacturer - his business card is tacked to the cork board above the printer. | |||

== External Links == | |||

[https://www.youtube.com/watch?v=rctPgALRUGU musical wiggly vase video] | |||

Documentation: | |||

* Outdated [[Type_A_Comic|comic strip instructions]] | |||

* [https://github.com/sudoroom/3DPrinting our own github documentation] | |||

* [https://noisebridge.net/wiki/3DPrintBeginners Noisebridge's 3D-printing documentation] | |||

* [http://typeamachines.com/ Manufacturer's website] | |||

** [http://cdn.shopify.com/s/files/1/0223/2361/files/Series12013StandardUserManualV1_6.pdf?6262 User Manual] | |||

** [http://support.typeamachines.com/hc/en-us Type A Machines Support Page] has lots of info on how to use and repair the printer. | |||

** [http://support.typeamachines.com/hc/en-us/articles/200213410-Replacing-the-Blue-Tape-on-the-Build-Surface Replacing the blue tape build surface] | |||

** [http://support.typeamachines.com/hc/en-us/articles/200022919-Cleaning-out-a-Filament-Jam Cleaning out a filament jam] | |||

** [http://forum.typeamachines.com/index.php Online Forum] | |||

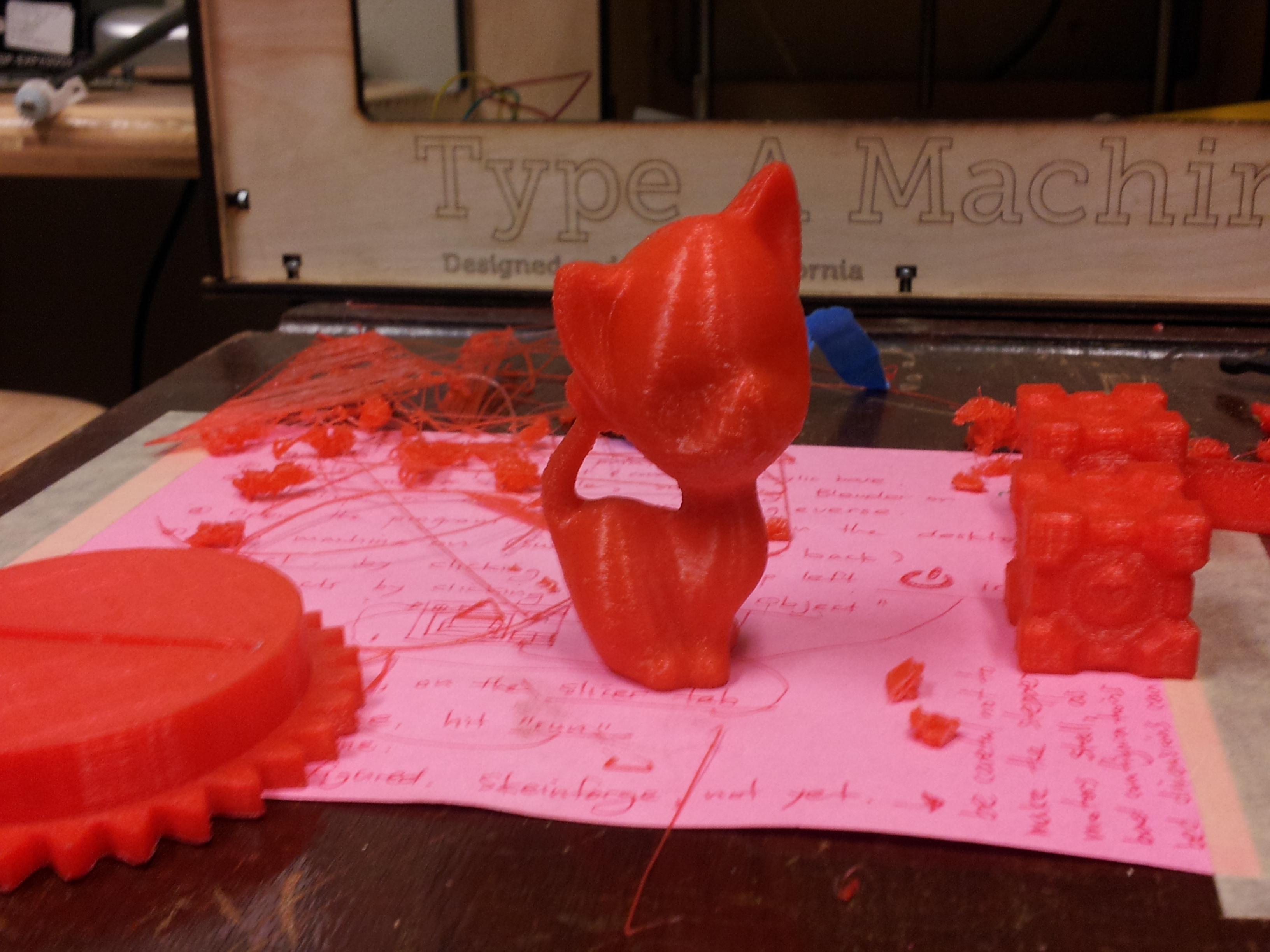

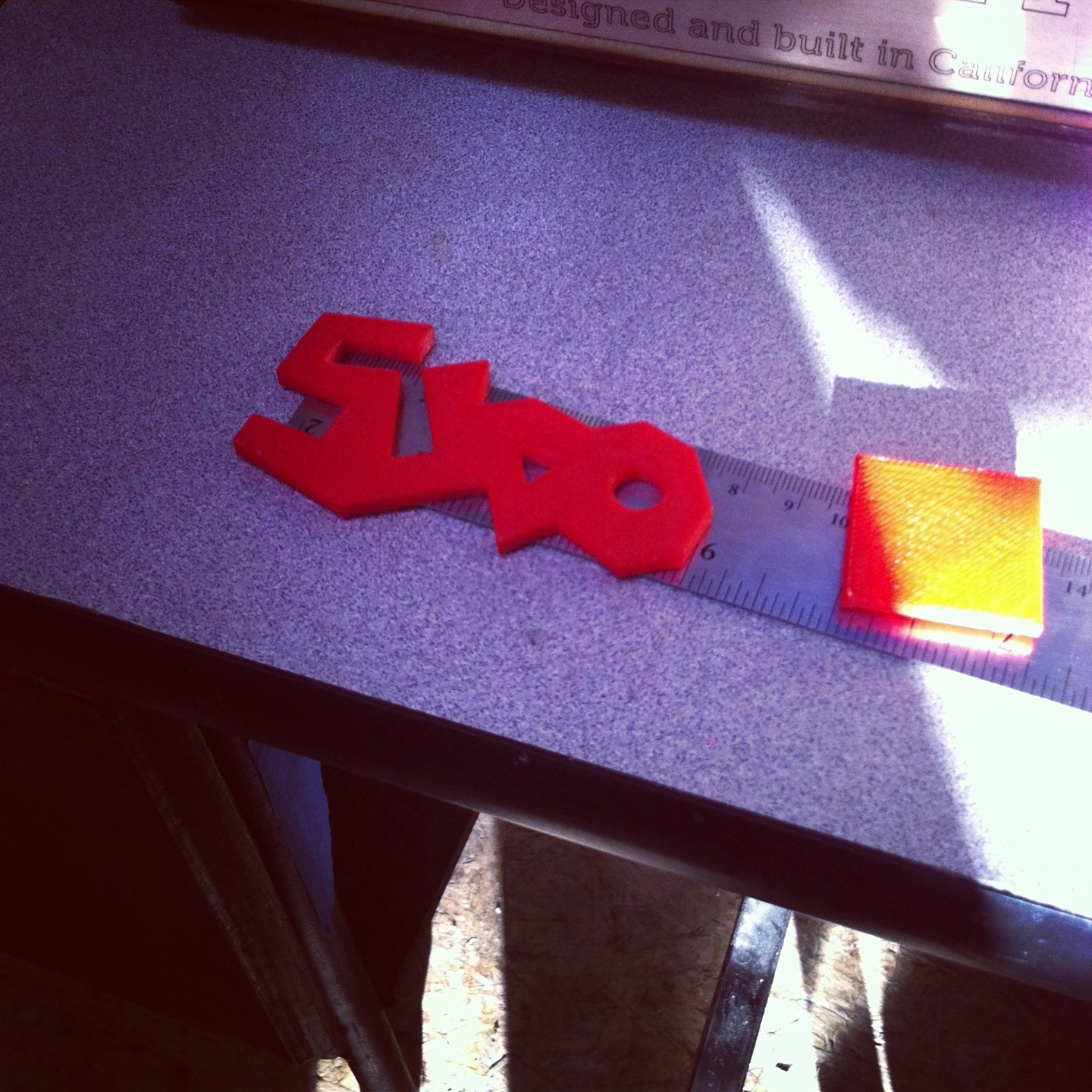

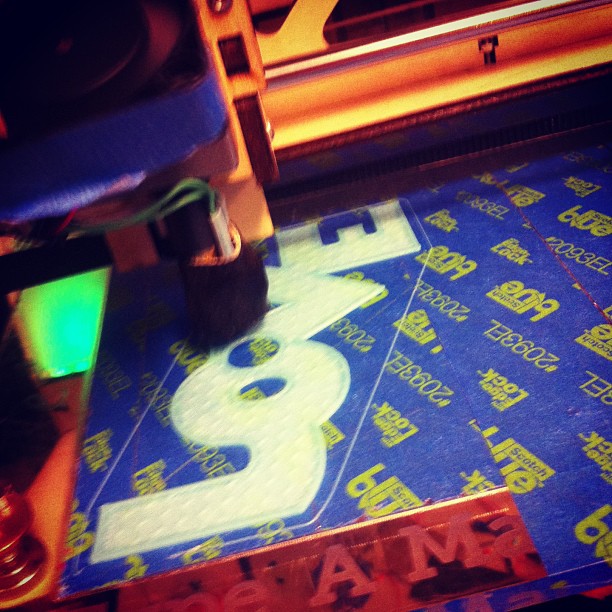

== Gallery of Creations == | == Gallery of Creations == | ||

| Line 46: | Line 57: | ||

3D_Printed_Cigar_Rocket.jpg | 3D printed 2-part rocket. 65mm max diameter, 29mm motor bay, tangent ogive curve with internal 2-way structural ribs and support for airspeed sensor pitot tube at nose. | 3D_Printed_Cigar_Rocket.jpg | 3D printed 2-part rocket. 65mm max diameter, 29mm motor bay, tangent ogive curve with internal 2-way structural ribs and support for airspeed sensor pitot tube at nose. | ||

</gallery> | </gallery> | ||

[[Category:3DPrinting]] | [[Category:3DPrinting]] | ||

Revision as of 18:43, 23 December 2013

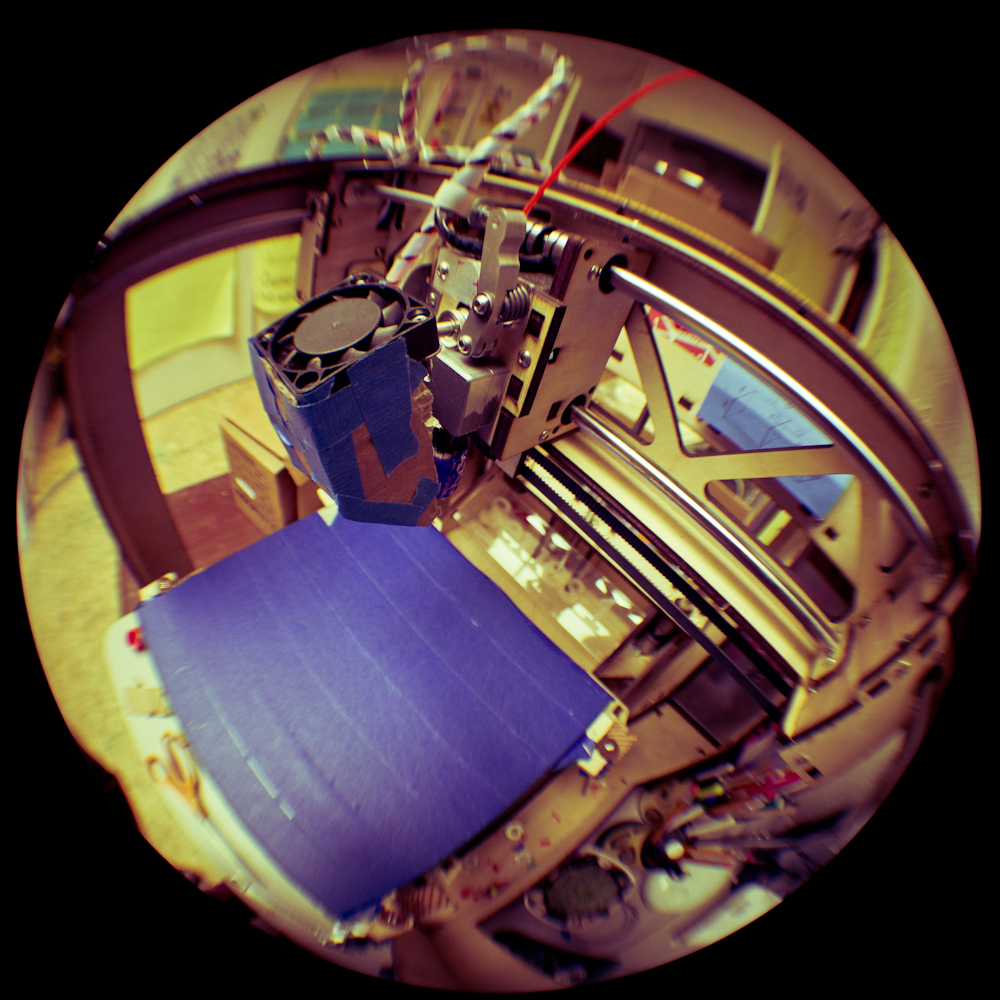

This is about a particular printer. There's a separate page about creating or acquiring 3D models.

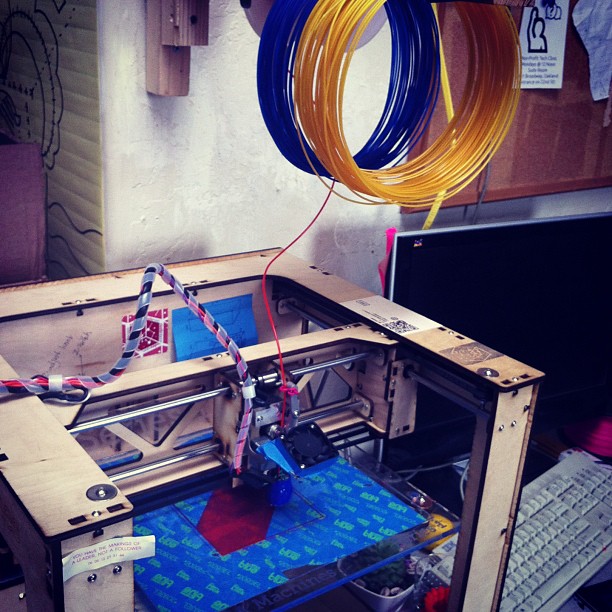

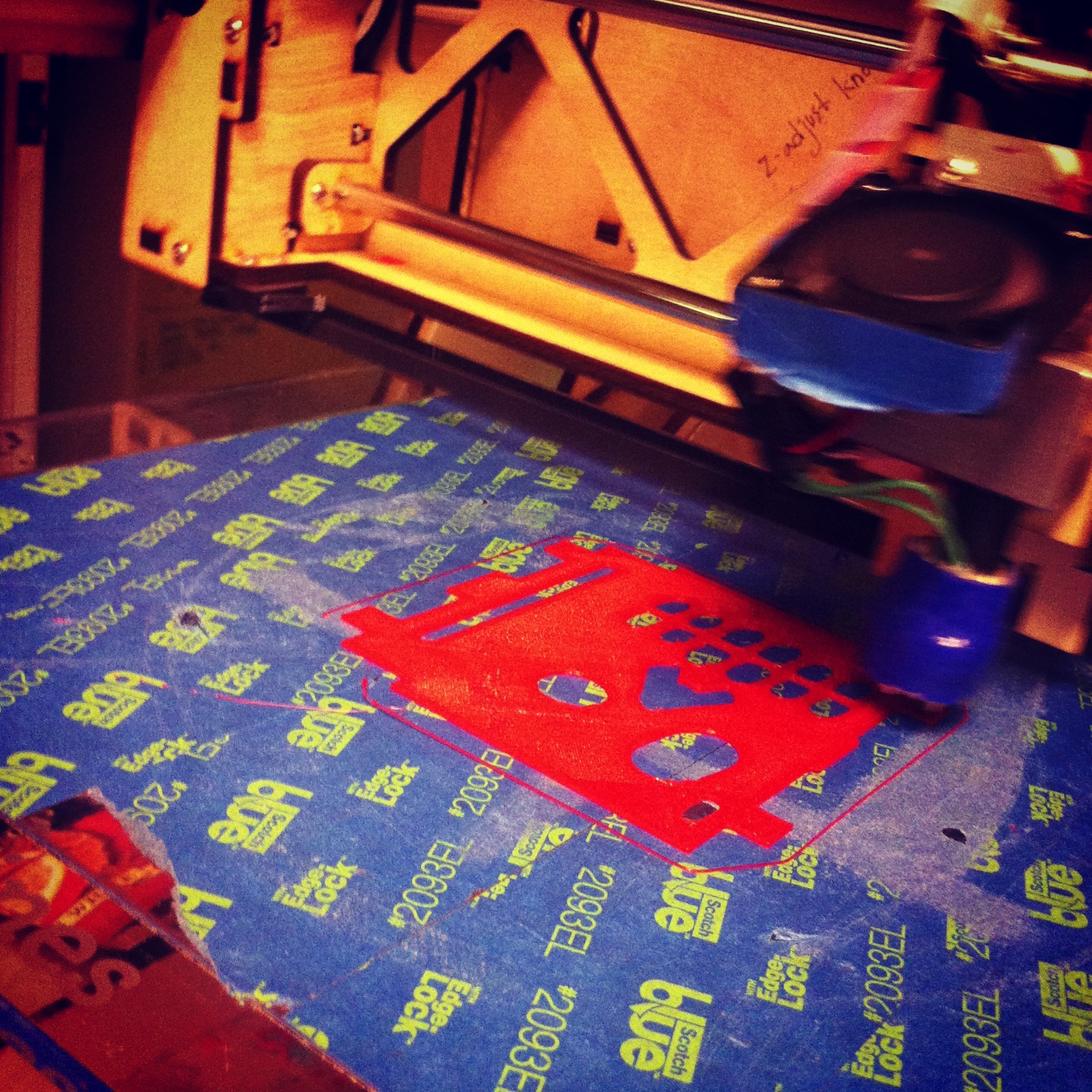

SudoRoom has a Type A Machine, currently our only 3D printer. It was generously donated by Jae Kwon in fall 2012.

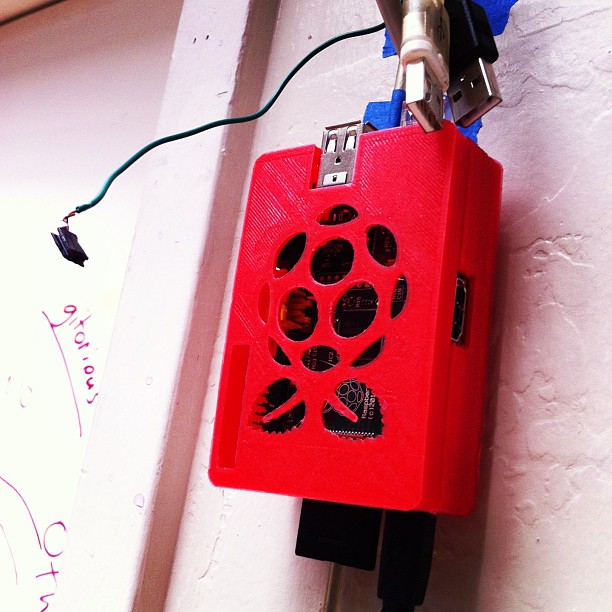

Attached Computer

The printer can attach to any computer by USB, but usually it's attached to a Linux machine called "sudodesk." It runs Linux Mint which does not have much helpful software in its repos, so the desktop user "sudoer" has these installed locally:

- slic3r (turns STL files into gcode)

- kisslicer (alternative to slic3r)

- pronterface (operates the printer, which accepts gcode)

Calibration

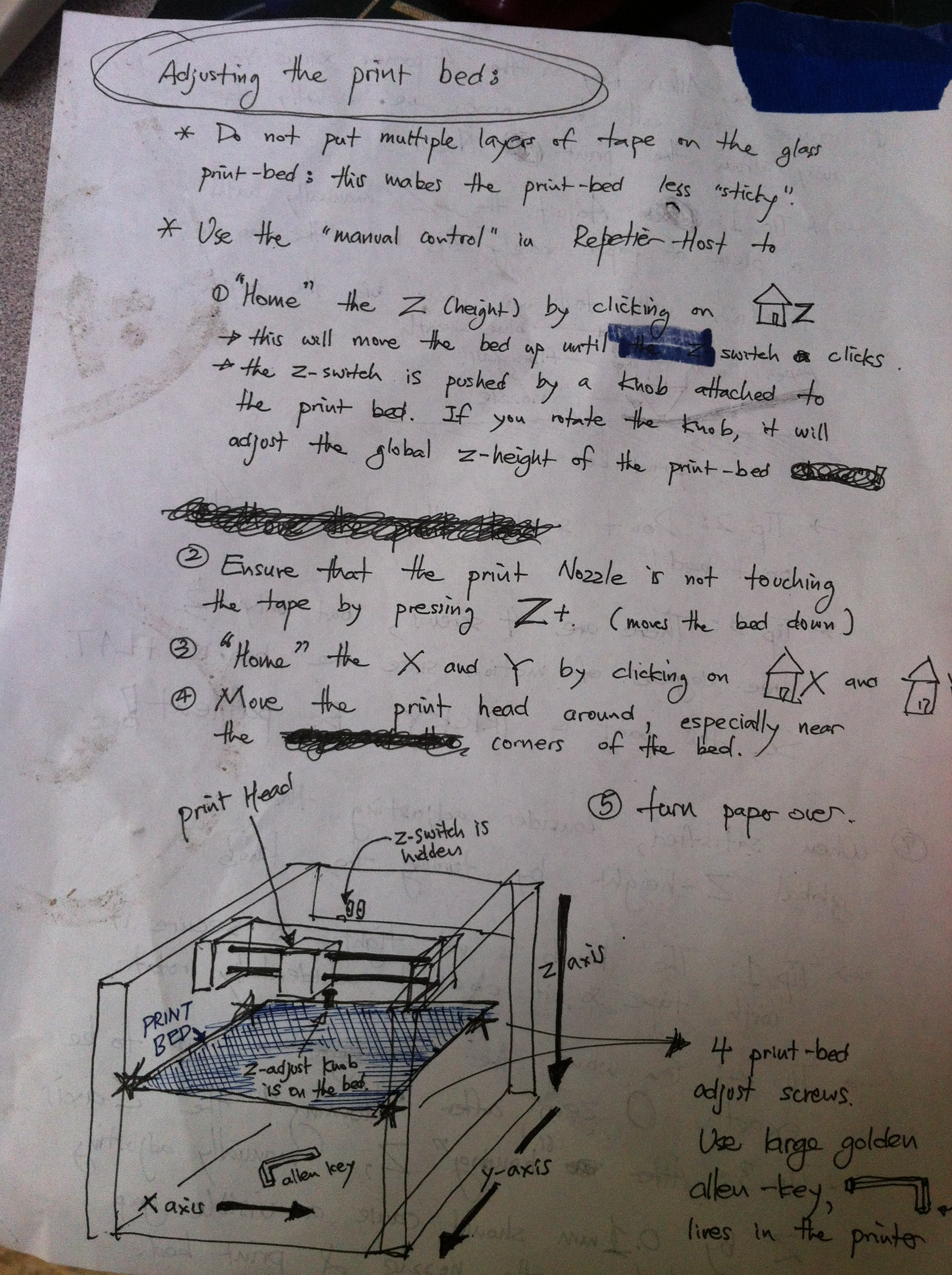

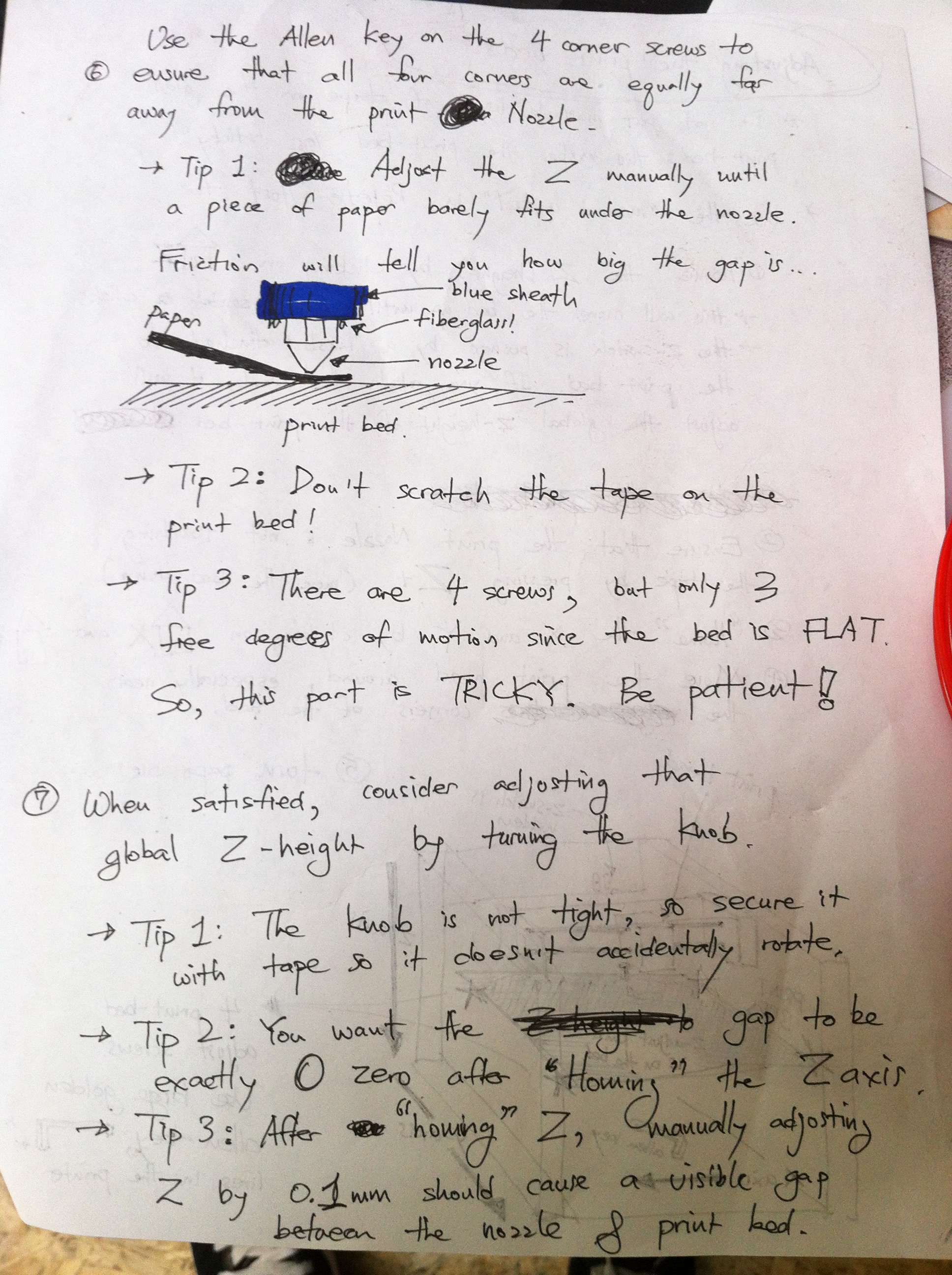

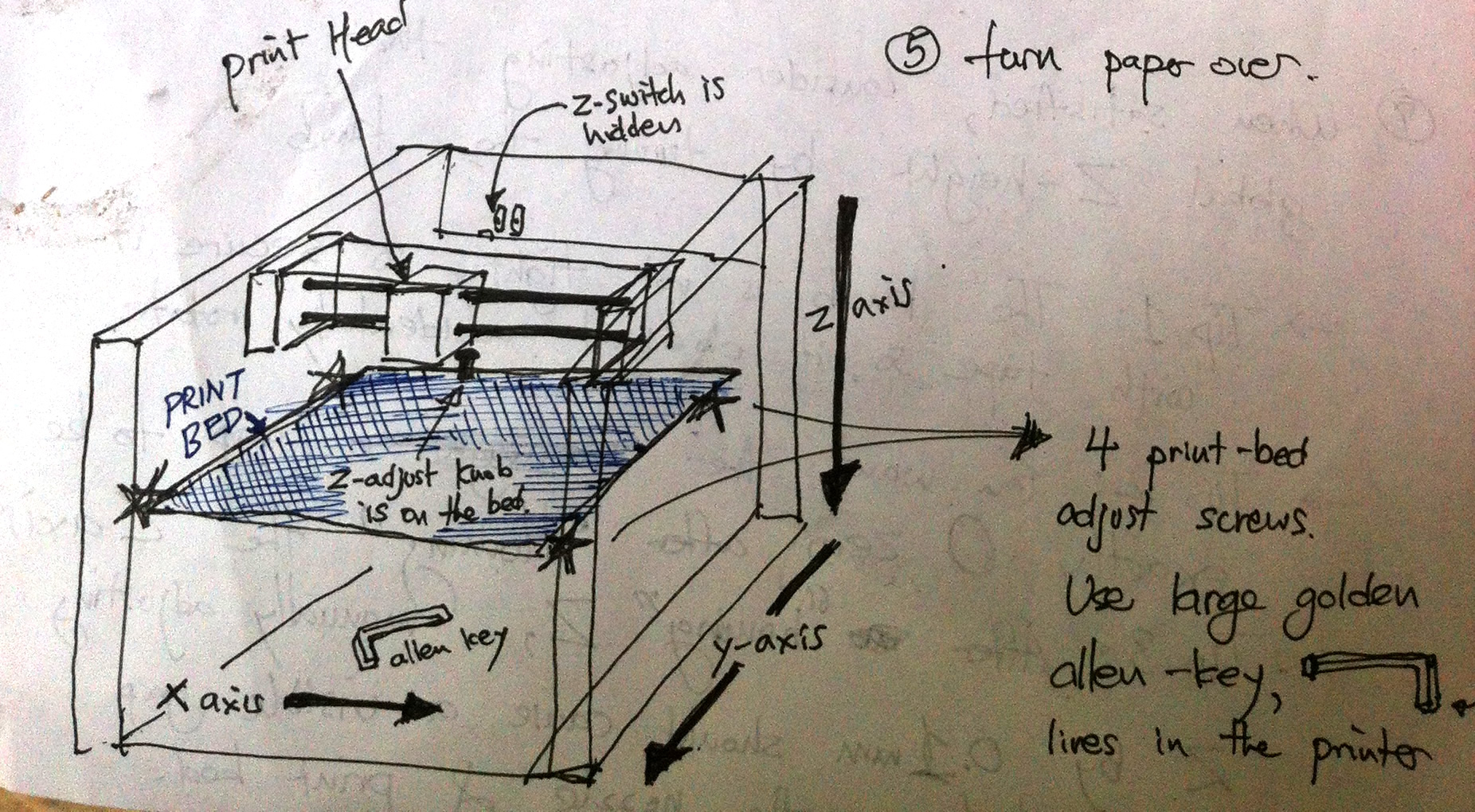

The bed & z-axis are often untrue. Some suggestions:

- Move the head around - is the bed flat? Test the Z roughly with an allan wrench laid flat on the bed (it should should barely flip up), then more finely with a piece of paper (it should create a slight friction only). Test on all four corners, adjusting the screws if necessary. Sometimes the middle might even be dipped in a bow. This will make it harder to print large objects...

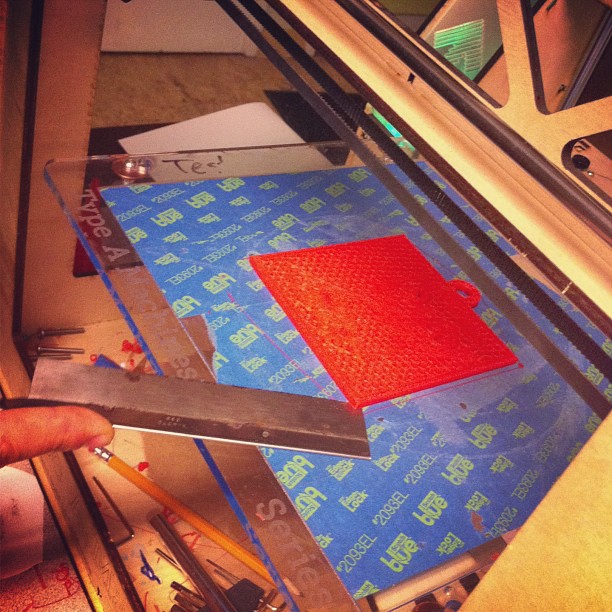

- Because the bed is not heated, prints will stick. You might need to pry them off with a razor. This often tears the tape, so we need to buy more tape. Usually we use ScotchBlue #2093EL.

Repair History

This printer has a long, colorful history of repair and disrepair. Most recently, Jake got it to work and reported to the list.

At least one Sudoer works for the manufacturer - his business card is tacked to the cork board above the printer.

External Links

Documentation:

- Outdated comic strip instructions

- our own github documentation

- Noisebridge's 3D-printing documentation

- Manufacturer's website

- User Manual

- Type A Machines Support Page has lots of info on how to use and repair the printer.

- Replacing the blue tape build surface

- Cleaning out a filament jam

- Online Forum