Difference between revisions of "CNC"

(I don't see a CNC mill here, is it hiding?) |

|||

| (8 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

'''CNC Mill''' or '''computer numerical controlled milling device''' is used for automatically milling or cutting away at materials like wood, plastic, or softer metals such as aluminum based on a 3D computer model. | '''CNC Mill''' or '''computer numerical controlled milling device''' is used for automatically milling or cutting away at materials like wood, plastic, or softer metals such as aluminum based on a 3D computer model. | ||

| Line 13: | Line 8: | ||

https://noisebridge.net/wiki/MaxNCMill#Toolchains | https://noisebridge.net/wiki/MaxNCMill#Toolchains | ||

= | == A big CNC machine with short Z height that we presently have == | ||

* [[JacksMill]] Jack gave us his CNC mill which we used to cut wood. It should also be able to cut soft metal like aluminum. It is located at the west wall, next to the robot control cabinet. | |||

[[File:Shapeoko.jpeg|right|thumb|Shapeoko CNC machine]] | |||

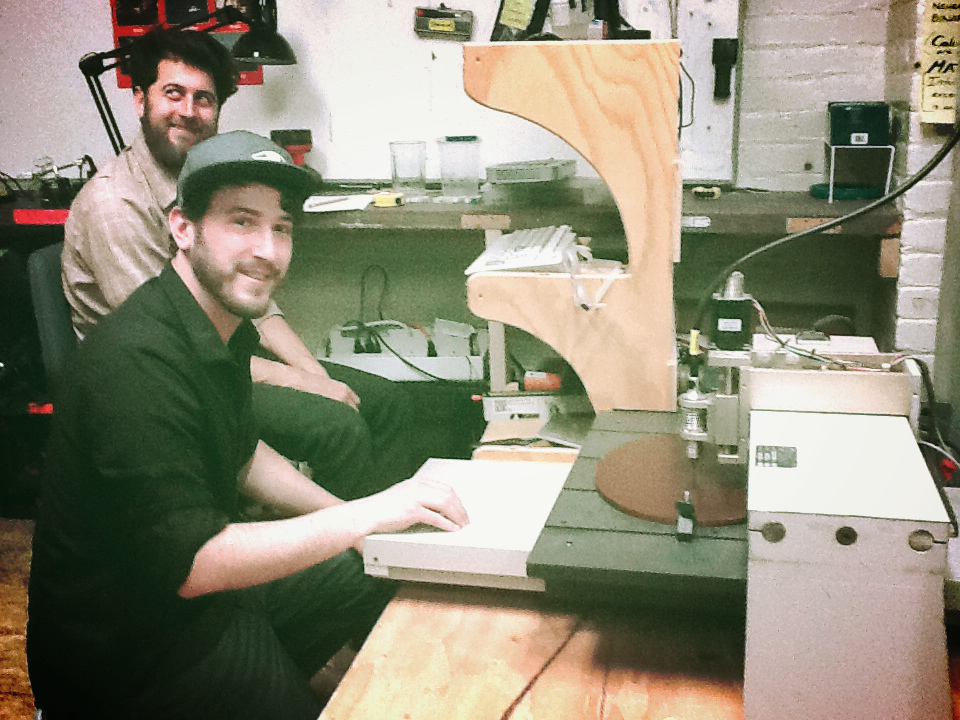

[[File:CNC Night at SudoRoom.jpg|250px|right|thumb|J teaches us how to use the old wood CNC Mill]] | |||

[[File:CNC Mill Cutting.jpg|thumb||250px|right|Cutting a wood sign]] | |||

[[File:Teaching CNC.jpg|250px|right|thumb|J teaching us how to cut on the CNC Machine]] | |||

[[Category:Machining]] | |||

[[Category:CNC]] | |||

[[Category:Tools]] | |||

== SHAPEOKO == | |||

https://jayscustomcreations.com/2015/02/shapeoko-2-cnc-mill/ | |||

there is a large CNC machine suitable for soft materials like soft wood and plastic (and possibly harder materials?) located under the table in the southwest corner of sudoroom. It's made of wood and acrylic, and the wood is painted white. Nicholas cleaned it really well but inside there was still a rats nest, and they had chewed through some of the wires. Presently the XYZ stuff is working fine with a 12V power supply, but the DC motor controller for the spindle is pretty dirty from rats and the wiring from the 48v power supply to it (and e-stop and speed control) are all disconnected right now. A bench power supply could operate the spindle very easily though. | |||

When plugged into the USB of a computer, it presents as | |||

<code>/dev/serial/by-id/usb-Arduino__www.arduino.cc__0043_7533531343735110F120-if00</code> | |||

<b>[https://github.com/Schildkroet/Candle2/releases/tag/latest this software CANDLE2 seems to work to move it around, but]</b> | |||

<i><b>the machine's Grbl settings are not calibrated, so it thinks a centimeter is about 8mm!!!!!</i></b> | |||

Connecing to it at 115200 baud, when pressing the reset button it says this: | |||

<code>Grbl 1.1f ['$' for help]</code> | |||

after $ and $$ queries, these are the responses: | |||

<code>[HLP:$$ $# $G $I $N $x=val $Nx=line $J=line $SLP $C $X $H ~ ! ? ctrl-x] | |||

ok | |||

$0=10 | |||

$1=25 | |||

$2=0 | |||

$3=0 | |||

$4=0 | |||

$5=0 | |||

$6=0 | |||

$10=1 | |||

$11=0.010 | |||

$12=0.002 | |||

$13=0 | |||

$20=0 | |||

$21=0 | |||

$22=0 | |||

$23=0 | |||

$24=25.000 | |||

$25=500.000 | |||

$26=250 | |||

$27=1.000 | |||

$30=1000 | |||

$31=0 | |||

$32=0 | |||

$100=250.000 | |||

$101=250.000 | |||

$102=250.000 | |||

$110=500.000 | |||

$111=500.000 | |||

$112=500.000 | |||

$120=10.000 | |||

$121=10.000 | |||

$122=10.000 | |||

$130=200.000 | |||

$131=200.000 | |||

$132=200.000 | |||

ok | |||

</code> | |||

[https://web.archive.org/web/20190331225723/https://wiki.shapeoko.com/index.php/Grbl_Configuration here is an incorrect Grbl Configuration on archive.org] | |||

[https://web.archive.org/web/20190924072420/https://github.com/grbl/grbl/wiki/Configuring-Grbl-v0.8 here is some info on configuring Grbl v0.8] | |||

[ | [https://github.com/gnea/grbl/wiki/Grbl-v1.1-Configuration here's a page about Grbl v1.1 which we have] | ||

It runs GRBL firmware. Commands such as "X10" or "Y-20" or "X15 Y20 Z15" work to move things around. There is no command for spindle control because it's not connected to the board. | |||

The XYZ movement motor controller is a [https://www.adafruit.com/product/1750|Synthetos gShield (grblShield) V5] arduino shield | |||

== A CNC Mill we no longer have == | |||

https://www.youtube.com/watch?v=AIGDspzMHD0 | |||

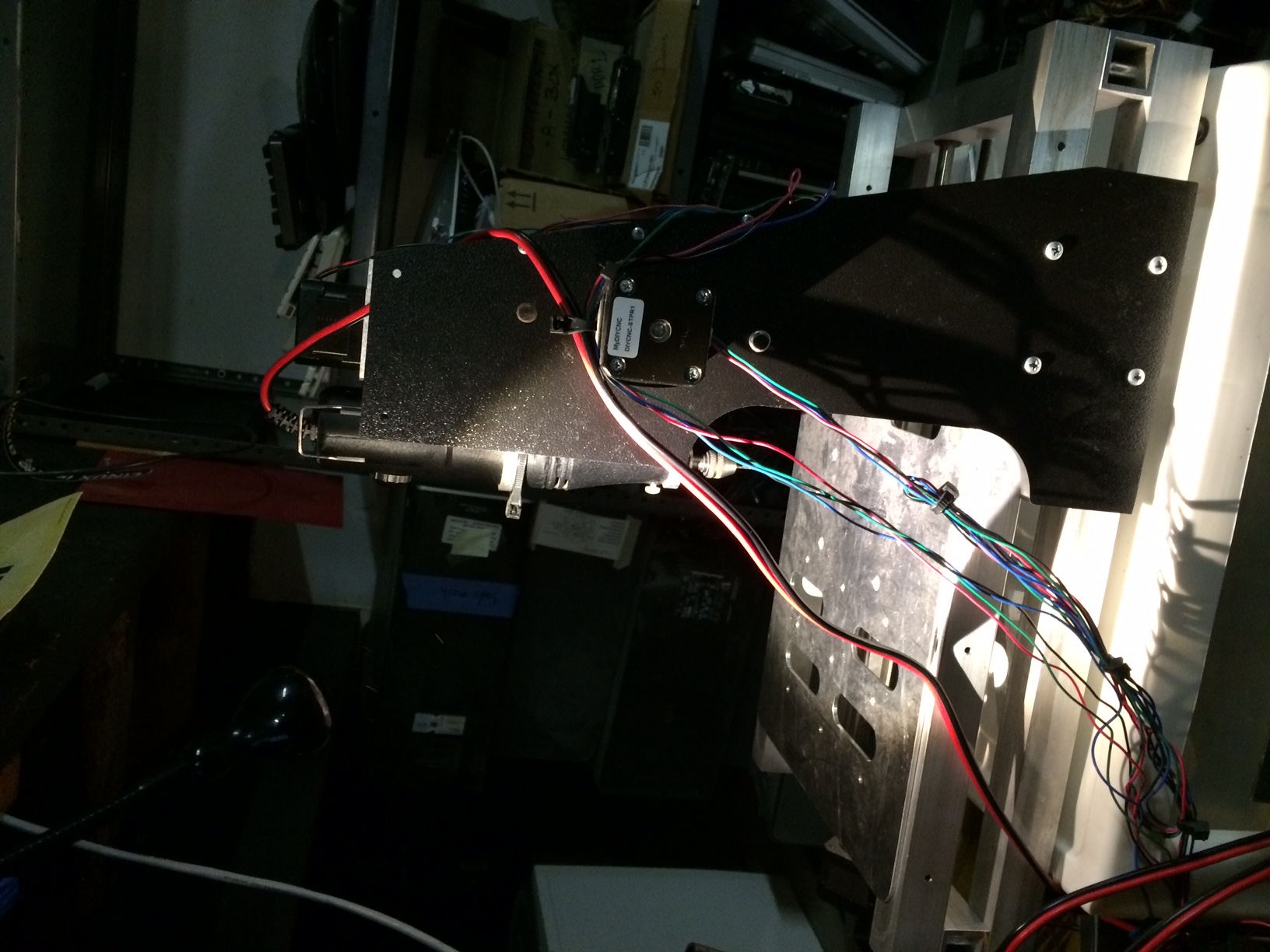

[[File:CNC | [[File:Our new CNC.JPG|thumb|right|a cnc we thankfully no longer have]] | ||

[[ | We had a small CNC Mill as of January 2015. It was donated by Pam and was traded away for a Quick Circuit 5000 (in the 3D printer area) | ||

It was a [[myDIYCNC]] [http://www.mydiycnc.com/project%20overview link] cnc thing | |||

[[ | [[File:Jake using the new CNC machine.JPG|550px|J using our new CNC - isn't it cute? Hope we can get more folks started on machining]] | ||

Latest revision as of 23:21, 27 February 2025

CNC Mill or computer numerical controlled milling device is used for automatically milling or cutting away at materials like wood, plastic, or softer metals such as aluminum based on a 3D computer model.

Akin to a 3D Printer, the CNC provides the ability to work with objects in x, y, and z dimensions. However, it provides subtractive manufacturing, rather than additive.

The sudo room sign by the intercom at the old 22nd st entrance was milled on such a machine!

The Noisebridge wiki contains much knowledge about using CNC mills for example TO MILL CIRCUITBOARDS: https://noisebridge.net/wiki/MaxNCMill#Toolchains

A big CNC machine with short Z height that we presently have

- JacksMill Jack gave us his CNC mill which we used to cut wood. It should also be able to cut soft metal like aluminum. It is located at the west wall, next to the robot control cabinet.

SHAPEOKO

https://jayscustomcreations.com/2015/02/shapeoko-2-cnc-mill/

there is a large CNC machine suitable for soft materials like soft wood and plastic (and possibly harder materials?) located under the table in the southwest corner of sudoroom. It's made of wood and acrylic, and the wood is painted white. Nicholas cleaned it really well but inside there was still a rats nest, and they had chewed through some of the wires. Presently the XYZ stuff is working fine with a 12V power supply, but the DC motor controller for the spindle is pretty dirty from rats and the wiring from the 48v power supply to it (and e-stop and speed control) are all disconnected right now. A bench power supply could operate the spindle very easily though.

When plugged into the USB of a computer, it presents as

/dev/serial/by-id/usb-Arduino__www.arduino.cc__0043_7533531343735110F120-if00

this software CANDLE2 seems to work to move it around, but

the machine's Grbl settings are not calibrated, so it thinks a centimeter is about 8mm!!!!!

Connecing to it at 115200 baud, when pressing the reset button it says this:

Grbl 1.1f ['$' for help]

after $ and $$ queries, these are the responses:

[HLP:$$ $# $G $I $N $x=val $Nx=line $J=line $SLP $C $X $H ~ ! ? ctrl-x]

ok

$0=10

$1=25

$2=0

$3=0

$4=0

$5=0

$6=0

$10=1

$11=0.010

$12=0.002

$13=0

$20=0

$21=0

$22=0

$23=0

$24=25.000

$25=500.000

$26=250

$27=1.000

$30=1000

$31=0

$32=0

$100=250.000

$101=250.000

$102=250.000

$110=500.000

$111=500.000

$112=500.000

$120=10.000

$121=10.000

$122=10.000

$130=200.000

$131=200.000

$132=200.000

ok

here is an incorrect Grbl Configuration on archive.org

here is some info on configuring Grbl v0.8

here's a page about Grbl v1.1 which we have

It runs GRBL firmware. Commands such as "X10" or "Y-20" or "X15 Y20 Z15" work to move things around. There is no command for spindle control because it's not connected to the board.

The XYZ movement motor controller is a gShield (grblShield) V5 arduino shield

A CNC Mill we no longer have

https://www.youtube.com/watch?v=AIGDspzMHD0

We had a small CNC Mill as of January 2015. It was donated by Pam and was traded away for a Quick Circuit 5000 (in the 3D printer area) It was a myDIYCNC link cnc thing